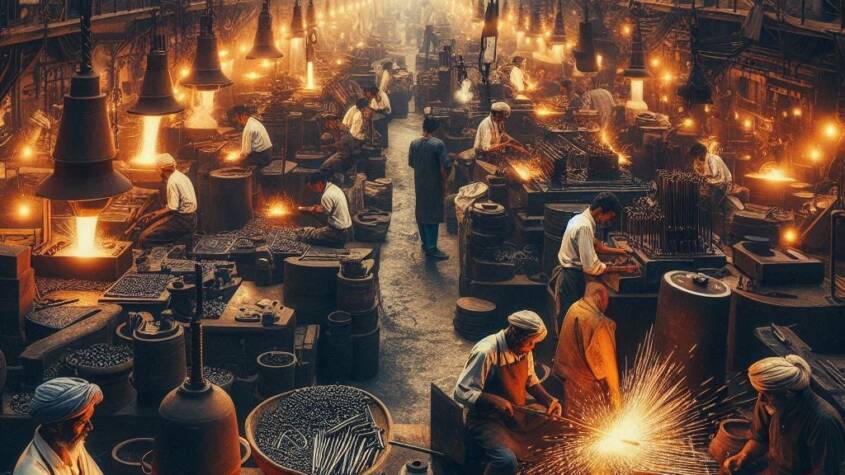

Indian Forging companies are investing heavily in developing new Advanced Technology Precision Forging & Lightweight Material Development which will allow them to increase their capacity for producing lighter weight & stronger components used on Electric Vehicles (EVs). The need for strong, yet lightweight motor shafts, gears, etc., is creating economic opportunities for the Indian forgers to create a greater variety of Alloy Steels, Lightweight Units & Near Net Forged Shapes. Additionally, most manufacturers are also upgrading CNC machining capability, Heat Treatment Applications & Quality Systems to comply with Electric Vehicle (EV) OEMs standards, and are working together with EV manufacturing companies to design low-cost, high volume, custom component solutions that utilize these technologies.

What energy-efficient technologies are used by Forging company in India?

Of late, there has been an increased shift by most Forging Company in India towards using energy-efficient technologies to minimize the carbon footprint and reduce energy usage while still producing products at an optimal level. This shift includes installing servo driven presses or induction heating systems that allow precise temperature control, recovering waste heat from furnaces, and utilizing energy-efficient heat treatment lines. In addition to this, many manufacturers implement automation, real-time energy monitoring systems, and optimized die design to reduce material losses and the need for re-work thus helping to reduce total energy consumed by their operations and contribute to more sustainable forging operations.

What role does metallurgical testing play in Forging company in India?

The metallurgical testing of forged materials allows forging companies throughout India to verify the strength, reliability and performance of their forged components in extreme conditions. Forging manufacturers use metallurgical testing as part of a detailed process to assess the properties of the forged materials they produce through various laboratory chemical analysis methods (e.g., metallurgical microscope, hardness testing, and mechanical property testing), to confirm the Quality of the forged materials, determine the quality of heat treatment, and detect defects that may occur during the manufacturing process. Consequently, compliance with OEM specifications, compliance with ASTM standards, and delivery of consistent quality are enhanced through metallurgical testing; and they are the means by which the forging manufacturers provide reassurance to their customers that they are providing a quality product that meets international requirements.

Best tips for choosing right forging company in India

Choosing a solid forging company in India may not be easy. You’ll need to conduct an extensive amount of online research which will include reviewing profiles for each company that you look at on Google My Business (GMB) as well as using reputable industrial directories, finding companies that are consistently listing in your search results. Next, after narrowing down your list of potential candidates, you will evaluate each company based on its experience in the industry as well as its production capabilities and ability to offer metallurgical processing services (heat treatment, material testing, etc.). A buyer should make sure that the forging manufacturer that they select can produce parts with high levels of accountability and compliance with international standards that allow for growth and stability.

Conclusion

A final thought is that through innovation, a commitment to sustainable practices and high quality, Indian forging companies will continue to strengthen their position as key participants in the global manufacturing supply chain as these companies meet the changing demands of the forging industry. The efforts of these manufacturers in preparing themselves for an emerging electric vehicle market with the use of advanced forging techniques and lightweight materials, coupled with energy-efficient methods of manufacturing and stringent metallurgical testing procedures to guarantee component reliability, have enabled them to provide high-quality, compliant, and economical forged components in the market today. The collective application of these techniques will enable the continued development of advanced transportation and support the use of sustainable production methods, while establishing India’s place as a provider of high-quality precision forged parts on a worldwide basis.

Freight Forwarding Services in Canada: How Progressive Cargo Simplifies Global Logistics

Freight forwarding plays a crucial role in today’s interconnected global economy. Business…